SERVICES

YOUR VISION IN METAL

There is no such thing as impossible

And we love a challenge! Whatever you have in mind, we want to make it happen. We love solving problems and we will find a way to turn your idea or vision into a real product – the perfect fit! We will provide expert guidance through every step of the production process, from design to selecting the materials and the strategy for processing. We can even provide specialist services and our holistic approach to customer service means that assistance with anything which takes place offsite is included.

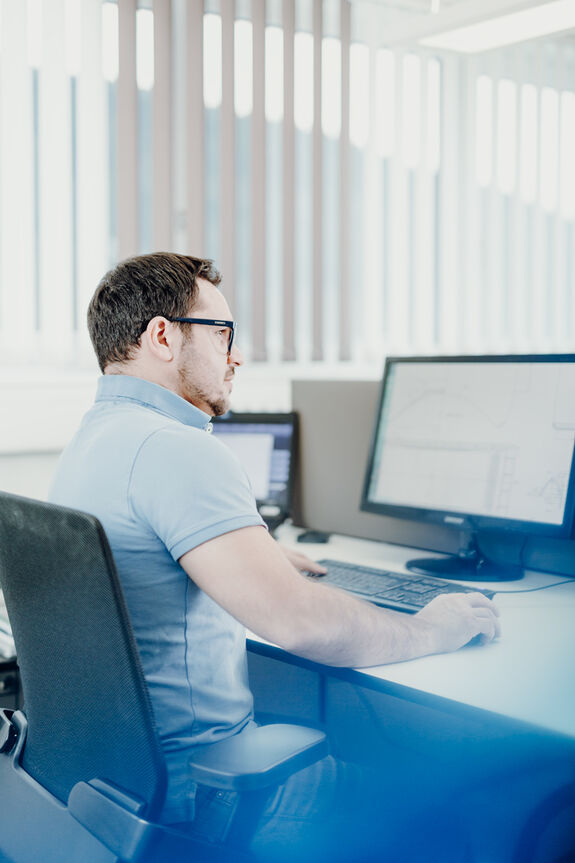

PLANNING, PROGRAMMING, DESIGN

We will be with you from the moment you bring your idea to us and we will manufacture your individualised product to your specifications. We will even design and make equipment to fit. To do this, we use CNC programs on our 3D-CAM equipped workstations to maintain our tools via DNC transmission.

To ensure there are no collisions in the machine’s process, we use a simulation in a CNC programme. This helps us to detect and remedy potential programming errors before production even starts – for you, that means a quick, smooth and cost-efficient manufacturing process.

Our technology allows us to implement improvements at the machine itself, meaning we can ensure maximum performance at any time. We will even write the report on the initial sample tests and the measurement log for you.

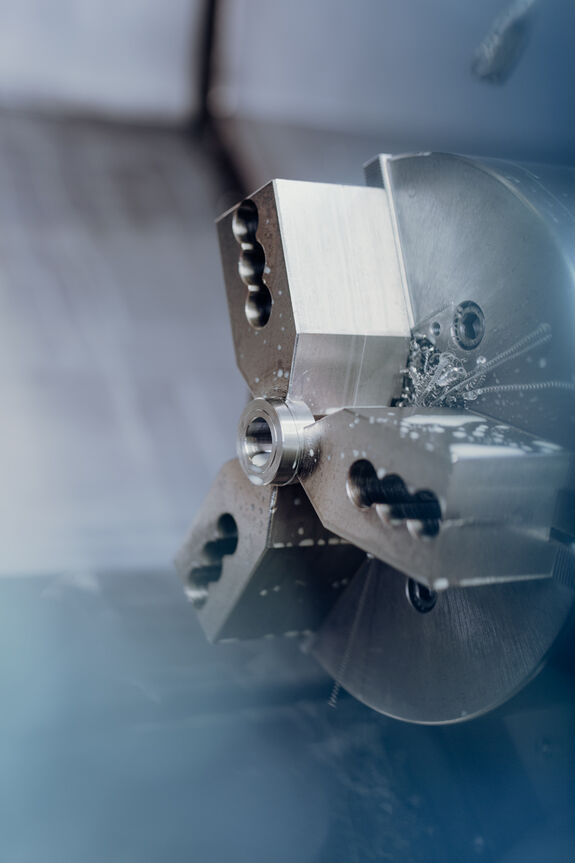

MACHINING

Whatever parts or designs you would like, we aim to make it for you. We have several CNC machining centres, some with motorised tools, and all with the latest process and control technology. We are ready for any challenge!

Our range of machining centres means we can work in lengths of up to 1,250 mm and a diameter of up to 650 mm.

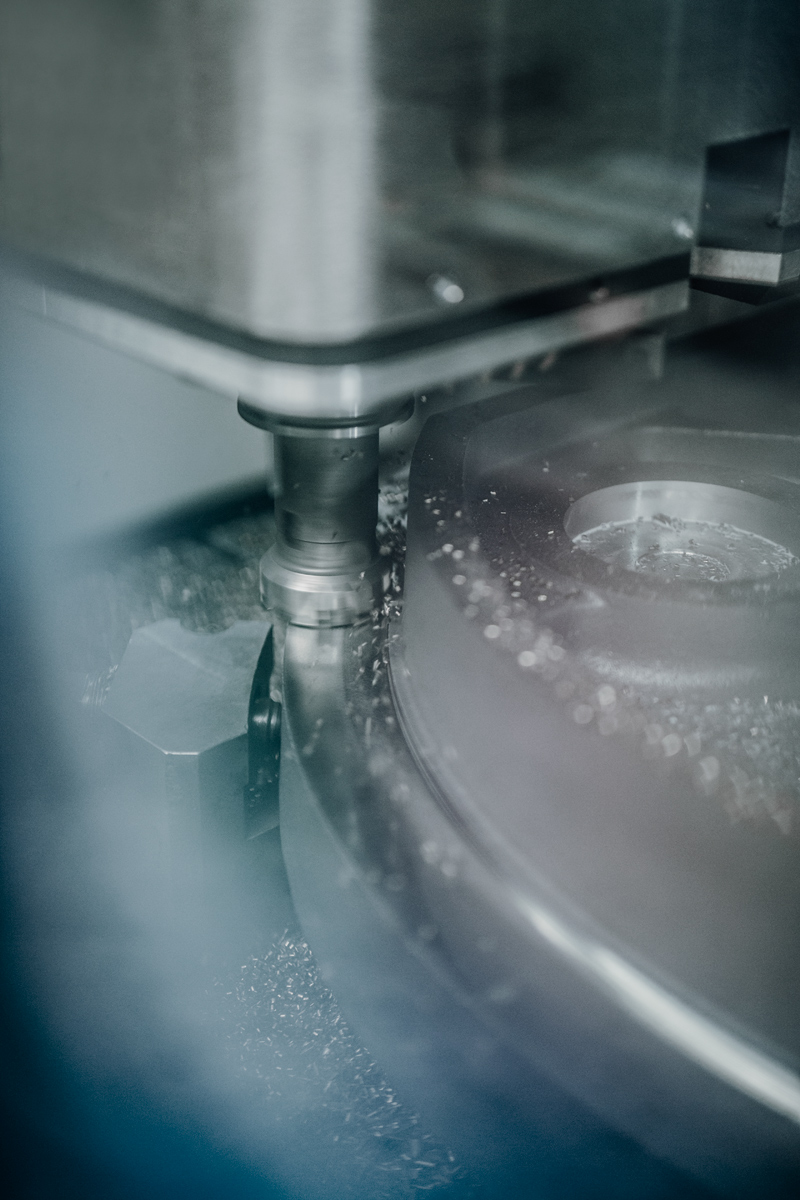

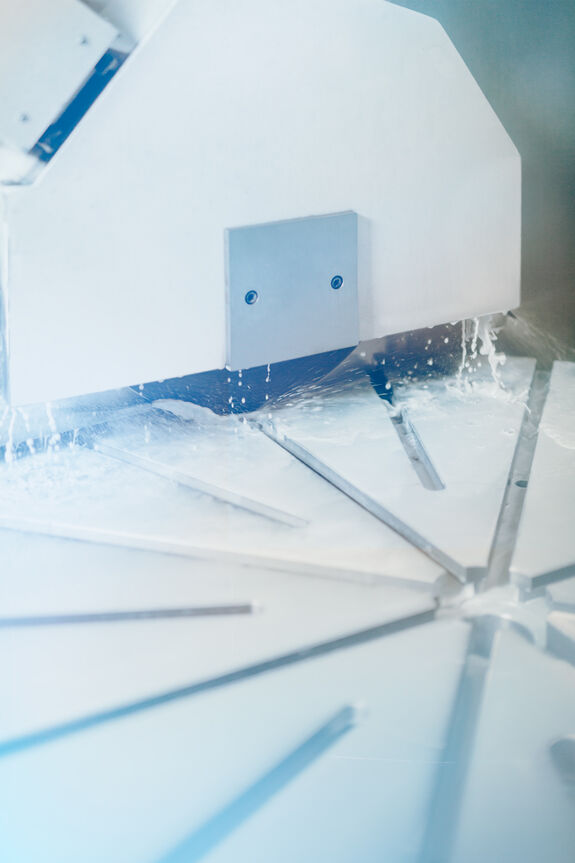

MILLING

Milling is one of our central areas of expertise, which is why you will find a huge range of horizontal and universal milling machines in our workshops. Our machines are equipped with pallet and tool changers, integrated gauges, an internal coolant supply, powerful gear spindles, process monitoring systems and much more, all to ensure that we are able to work with precision measured in micrometres.

Our facility boasts over 40 milling machines with maximum traverses of 500 mm to 3,400 mm. These include 3-axis vertical machines, 4-axis horizontal processing centres and even 5-axis processing centres. 5-way milling technology is the basis for our precise and comprehensive processing over a diverse range of workpieces.

Please speak to us if you have a special request and we will work with you to come up with a way to implement it.

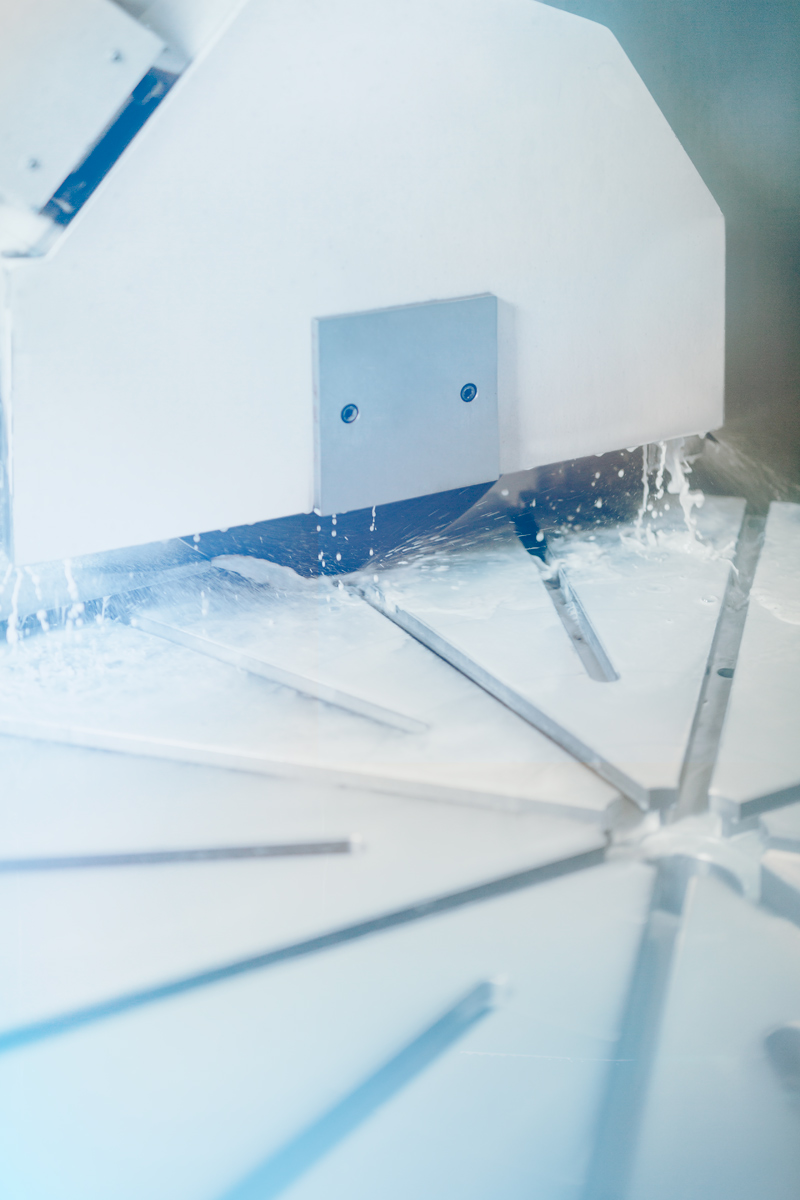

GRINDING

We use a range of processes to finish the surface of your product to your specifications: smooth, matte or high-polish.

We have several flat and cylindrical grinders for precision machining. They allow us to achieve high precision, measured in micrometres, and to work with rotationally symmetric or cubic workpieces of any size.

MODULAR ASSEMBLY

Assembling modules from individual components and full machines provide the finishing touch to our range of skills and services. We manufacture the individual components and then specially trained staff assemble your precision module, including electrics, hydraulics and pneumatics. That means that you get everything in one place, saving you time and money.